Ugh man sorry for your pain on that one!!!

Thank you.

Anyway. Ripped out floor, dried out thorougjly, cleaned with Concrobium mold killer, dried out thoroughly again and reinstalled flooring.

Before moving all the stuff back into the office, I figured this was a good time for a flow/leak test.

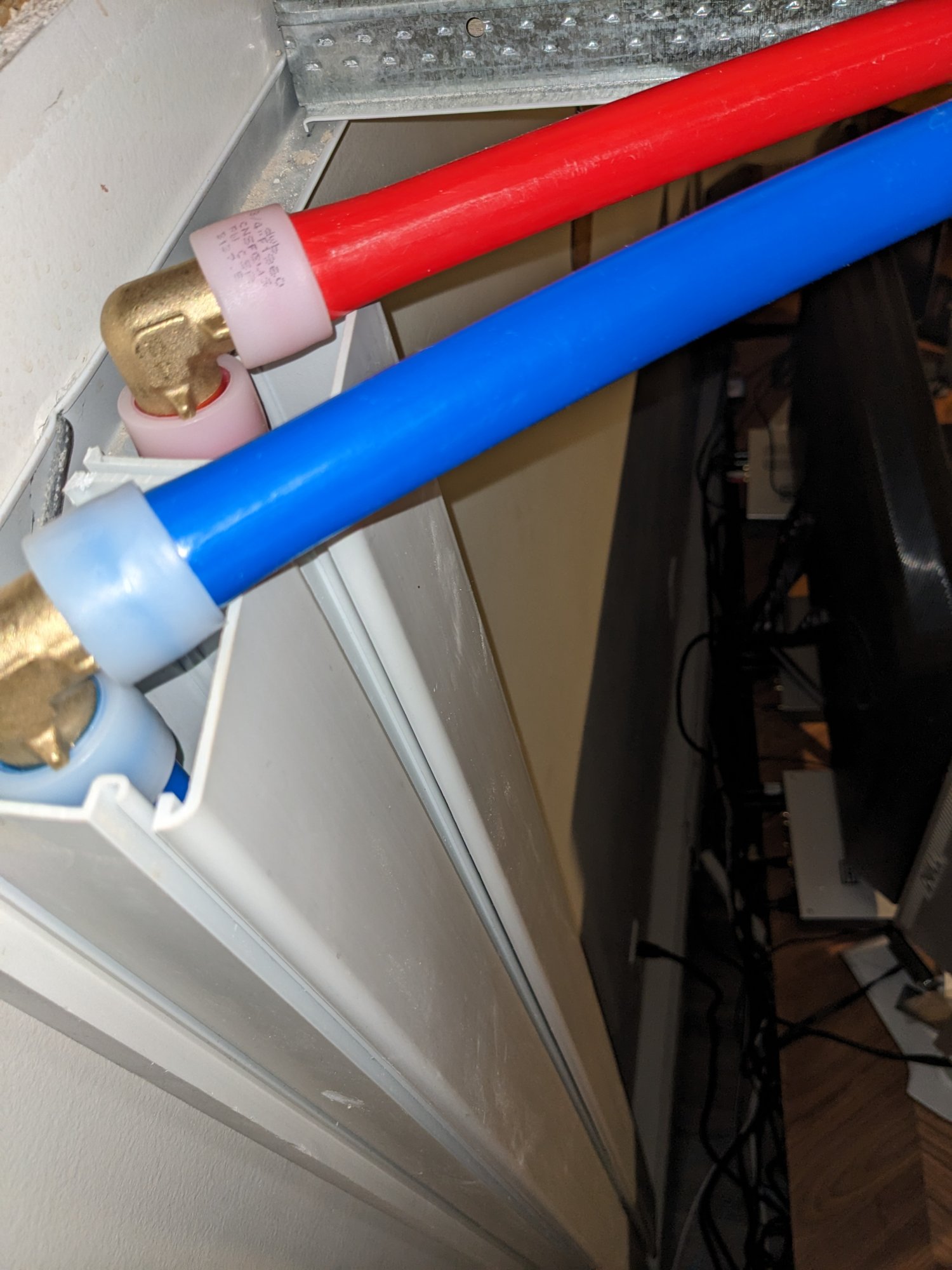

I connected the two QDC connections together as follows:

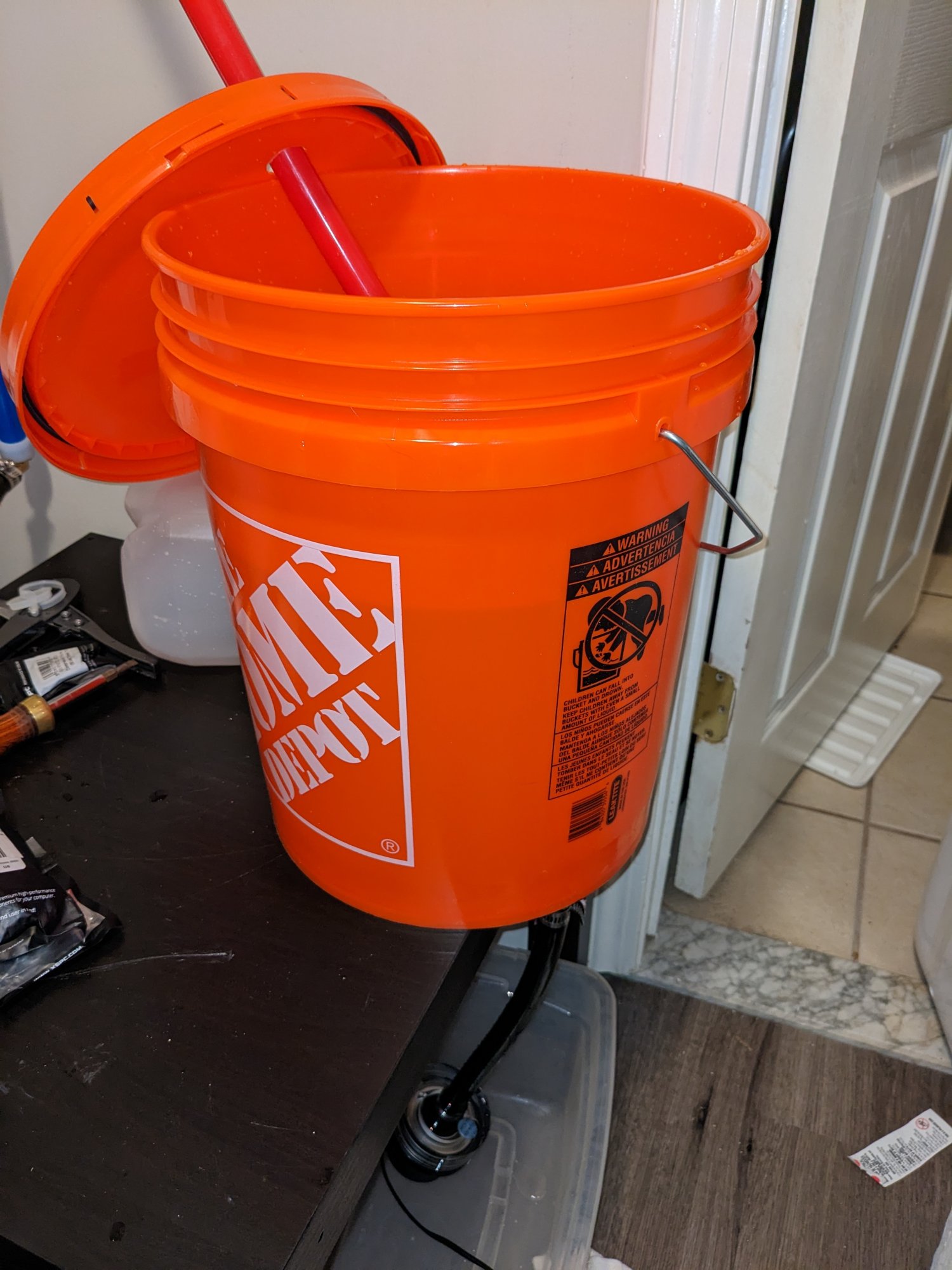

I hooked up a Home Depot bucket as a temporary test reservoir:

Right off the bat, we had a leak, but luckily only in the temporary bucket reservoir.

It seems as if when you tighten down the through hole fitting, the rubber o-ring tends to want to pop out one side. :/

I may have to do some research and find a better through-hole seal than this when I build the final reservoir.

Anyway, the rest of the loop held water. No other leaks.

The return flow looked somewhat tepid, so I was concerned and tested flow by holding a 1 gallon jug under the return hose. (no pics sorry, needed both hands for this)

Turns out it fills a 1 gallon jug in about 30 seconds, so that's 2 GPM. I guess the larger diameter of the 3/4" PEX just makes things look a lot slower than I am used to with 3/8" ID tubing

Now, that is pushing water through 1 QDC connection, but there are no blocks in the loop. Blocks will definitely slow things down. How much I don't know.

I considered hooking up an old CPU and GPU block on the PC side to make the test more realistic, but I completely forgot.

So real flow will be slower due to more resistance, but I will also have two D5 pumps in series in the final design. This test used only one.

Another interesting side note is that the loop used way less coolant than I had calculated using L*pi*r^2. I'm thinking this is probably due to there being no backpressure from blocks resulting in the long flat tubes in the ceiling not filling all the way. I expect the final thing taking more coolant to fill it.

Side note: I have grand plans for how to drain the finished loop, but I failed to plan for this for the temporary test loop which made for a bit of a mess.

I also learned that the 500w DataVac blower is NOT sufficient to blow out the coolant out of the whole loop. I had to do one half at a time.

Anyway, that's it for now.