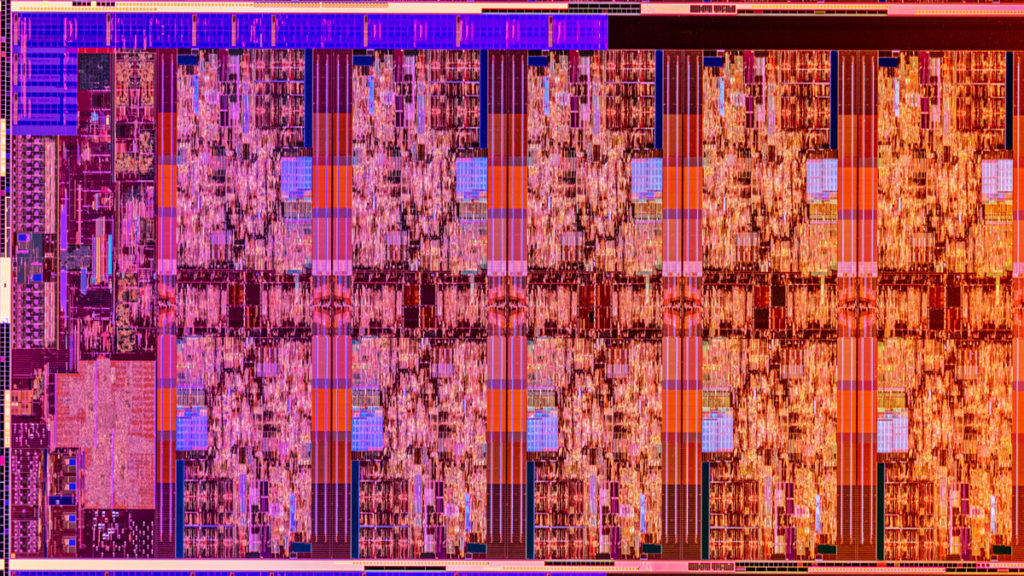

Image: Intel

With their increased core counts, temperature has become a rising concern with Intel’s recently unveiled Core S-series desktop processors, but the company has made some under-the-hood tweaks that should make it easier to keep thermals in check. According to a slide from the official Comet Lake-S deck, Intel implemented a thinner die STIM, which allowed for a thicker integrated heatspreader (IHS).

“On top of a processor sits an area of inactive silicon, and silicon is a terrible heat conductor, at least when compared to copper,” explained OC3D. “With Comet Lake, Intel has thinned this...

Continue reading...

Last edited by a moderator: